What is Silk Fiber?

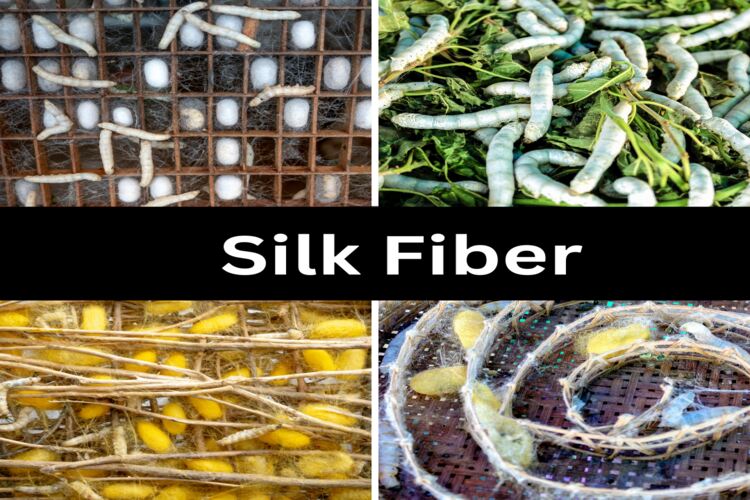

Silk fiber comes from silkworms. They make it by spinning cocoons. Silkworms are scientifically called Bombyx mori. To get silk fiber, we start by taking care of the silkworms, and then we take out the silk textile fiber from the cocoons.

History of Silk Fiber

Silkworm rearing began in China 5,000 years ago with Bombyx mori. Ancient Chinese people discovered how to unwind the cocoons and weave exquisite fabrics from silkworm threads. Silk was so valuable that only Chinese royalty could wear it.

Chinese silk-making methods were secret for centuries. Around 300 A.D., sericulture spread to Korea and Japan. In 552 A.D., two monks took silkworm eggs to Europe, starting the Western silk fiber industry. Silk culture expanded in Europe and Asia.

In the 13th century, the English started silk production but struggled due to their climate. Silk culture began in America in 1603 with silkworm eggs and mulberry seeds sent to Virginia by King James.

The English wanted to rival the French and Italians in silk, so they had American colonists raise silkworms. Silk production in Virginia and Georgia was sporadic until the 1760s when cotton and tobacco became more profitable.

Around 1760, Nathaniel Aspinwall promoted silk cultivation in Mansfield and nearby areas. He introduced silkworm eggs in 1762 and, with Dr. Ezra Stiles’ help, persuaded the legislature to support silk culture with incentives and mulberry seed distribution.

Properties of Silk Fiber

- Strength: Silk fiber is very strong because of its orderly linear structure and abundant hydrogen bonds. However, they weaken when exposed to moisture as water dissolves these bonds.

- Flexibility: Silk fibers are highly flexible and can stretch without breaking. Silk fabrics are also resistant to wrinkling.

- Water Absorption: Silk fiber can absorb water efficiently, making it comfortable to wear in both summer and winter. It’s more absorbent than cotton but less so than wool.

- Heat Resistance: Silk breaks down at high temperatures exceeding 1000°C.

- Electrical Properties: Silk fiber has low electrical conductivity and tends to build up a static charge when handled.

- Corrosion Resistance: Silk fabric is resistant to corrosion.

- Sunlight: Prolonged exposure to sunlight can change the color of silk fibers as ultraviolet rays break down peptide bonds and lead to yellowing. Oxidation of the fiber’s surface also contributes to this change in color.

Processing of Silk

Charkha Reeling: This method uses both manual and powered reeling machines and is commonly used in the Indian reeling industry’s home-based sector. A typical charkha includes three main parts: a clay platform, a distributor, and a reel. In this process, cocoons are boiled and reeled in the same bath. On average, each charkha produces about one kilogram of raw silk fiber per day.

Cottage Basin: In this method, the cocoon is first boiled separately in a basin and then reeled in a hot water basin connected to the reeling seat. Each basin typically has 6-8 ends, and each silk strand is passed through a button to remove impurities. The silk fiber is wound onto a small reel and then rewound into standard skeins. The average daily silk production per basin is approximately 800 grams.

Filature Basin: Multi-end filature basins are equipped with boilers and use steam for both cooking and reeling. This method includes additional tools like Jetta-bouts to aid in thread handling and improve cocoon feeding efficiency. Individual brake mechanisms are provided for each reel. On average, filature basins yield about 600-800 grams of silk fiber per day.

Spun Silk: Spun silk is used in filling cloth filaments because it’s more cost-effective than reeled silk. Spun silk fiber requires extra twisting to secure the shorter fibers. After boiling to remove the gum, the fibers are dried and then combed to separate, straighten, and align them. Following this, the fibers are passed between the reels multiple times.

Advantages of silk fiber

- Strength & Durability: Silk, despite its softness, is one of the strongest natural fibers and is often mixed with other fibers like cotton to make it even more durable.

- Absorbency: Silk fabric’s capacity to absorb moisture makes it perfect for dye absorption, and its high absorbency also makes it breathable.

- Texture: Silk fabric has a luxurious sheen and an incredibly soft, lightweight texture that feels exceptionally smooth on the skin.

- Recyclable and Biodegradable: Silk is a natural material that is very biodegradable. A biodegradable fiber is a fiber that can be broken down by bacteria alone over time.

Disadvantage of silk fiber

- Shrinkage: Silk fabric may shrink when washed, so it’s best to opt for dry cleaning to prevent this issue. Keep in mind that some manufacturers pre-wash the fabric before using it in clothing, which can increase the overall cost.

- Cost: Silk is not only a more expensive fabric, but it also comes with higher maintenance costs. Dry cleaning services can be a significant expense, and silk requires special care and attention.

- Sun Damage: While silk is generally durable, prolonged exposure to sunlight can weaken the fibers, leading to material weakening, faster color fading, and a greater risk of tearing compared to other materials.

- Water Damage: Silk can absorb a considerable amount of moisture, but it’s prone to water stains that can be quite challenging to remove.

Uses of Silk

Silk clothing, like other natural textile fibers, is incredibly comfortable. Silk fibers are commonly used for making shirts, ties, blouses, high-end fashion items, underwear, pajamas, and robes. There is a wide variety of silk fabrics to choose from, including charmeuse, shantung, crepe de chine, dupioni, taffeta, and chiffons. Silk has applications beyond clothing, as it is used in wall coverings, upholstery, carpets, and bedding. Silk’s versatility extends to various industries, where it is used in manufacturing parachutes, bicycle tires, artillery gunpowder bags, and non-absorbable surgical sutures.

You may also like:

- Nylon Fiber: Properties, Advantages and Disadvantages

- Kapok Fiber: Properties, Structure and Production Process.

- What is Linen Fiber? Properties, Structure, and How It Made?

- What is Jute Fiber? Properties, Advantages and Disadvantages.

- What is Hemp Fiber? Properties, Advantages and Disadvantages.

- What is Ramie Fiber? Properties, Advantages and Disadvantages.

- What is Sisal Fiber? Properties, Structure, and How It Made?

- Pina Fiber: History, Properties, Production Process

- Coir Fiber: Properties, Production Process and Advantages

- Wool Fiber: History, Properties, Production Process

- Acrylic Fiber: History, Properties, Advantages and Disadvantages

- What is Textile? Definition and Meaning

- Olefin Fiber: History, Properties, Advantages and Disadvantages

Share this Article!