Definition of textile fibers

Textile fibers are materials primarily derived from natural or synthetic sources. Fibers are the fundamental elements utilized in producing textile yarns and fabric and it is the tiniest visible components of textile products.

Table of Contents

Properties of textile fibers

- Staple Fibers: Staple fibers are fibers of a short length, usually measured in inches or small parts of an inch, and they have a limited length. Short staple fibers have a maximum length of 60 mm.

Filament: Filament threads are long and unbroken, while staples are shorter, typically just a couple of inches in size.

Texture: It’s the sensation you experience when your hand glides over a texture. Basic-level paraphrases and fabrics that are considered staples can have a slightly coarse texture, whereas filaments and fabrics made from filament fibers have a smooth feel.

- Resilience: The ability of textile fibers to regain their initial form once external force is gone is known as fiber resilience.

- Luster: It is how light bounces off an object, typically not as bright as a gleam. Silk and man-made fibers tend to possess greater shine than plant-based fibers. Man-made fibers frequently begin with a strong shine that is purposely decreased during the spinning process.

- Static Electricity: Static electricity occurs when the power of electrons or ions becomes excited between the surfaces of two substances because of rubbing. When these surfaces come apart, it leads to the buildup of electrical charges.

- Crimp: Fiber crimp pertains to the curly design in a textile fiber, typically assessed as waves or curls per distance or as the variation in length when the fiber is made straight.

- Elasticity: Stretched material can promptly go back to its initial size.

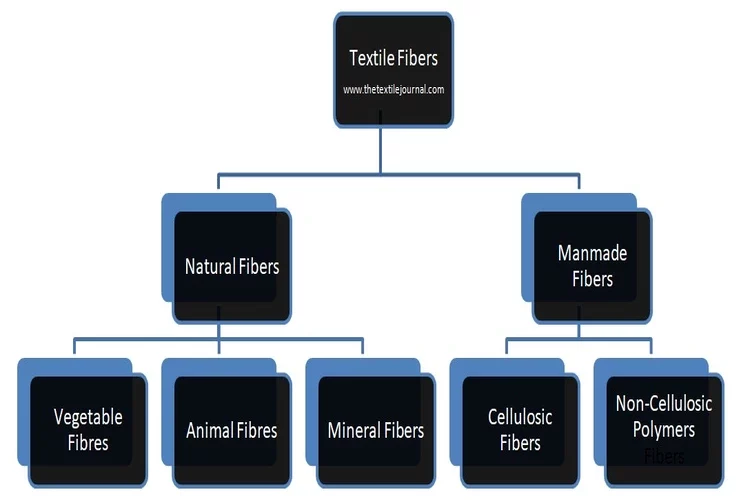

Different types of textile fibers

Textile fibers are generally classified into two categories according to where they come from.

- Natural fibers: Natural textile fibers are created from substances obtained straight from plants, animals, or minerals. The unprocessed, organic substances are transformed into strands and threads, which are then woven or knitted into fabrics of natural source.

- Manmade fibers: These textile fibers are artificially manufactured by humans and do not occur naturally in the environment. Man-made fibers are characterized by their high strength, resilience when wet, and low moisture absorption properties. Examples of man-made fibers include viscose rayon, acetate rayon, nylon, polyester, and others.

Types of Natural fibers

Vegetable fibers:

Plant fibers are known as vegetable fibers. Plant life contains cellulose, a crucial element made up of carbon, hydrogen, and oxygen. These plant-based fibers share characteristics such as poor springiness, thick consistency, efficient transfer of heat, strong capacity to soak up liquids, and ability to withstand high levels of heat. Some types of plant-based fibers are cotton, Kapok, Linen, Jute, Hemp, Ramie, Sisal, Coir, and Pina.

- Cotton: Cotton is the most extensively cultivated natural textile fibers worldwide, primarily stemming from the seed coat, which surrounds the outer layer of the cotton plant’s seeds.

- Kapok: Kapok trees, typically found in tropical forests, yield fiber through the process of opening their pods and extracting the seeds and fibers.

- Linen: Linen fiber is derived directly from the flax plant, where fibers are meticulously extracted, spun into yarn, and woven into long, comfortable, and resilient sheets of fabric known as linen fabric.

- Jute: The long, soft, and lustrous fibers are transformed into sturdy threads, serving a wide range of purposes. Jute fiber ranks second only to cotton in terms of production and is often called the ‘golden fiber’ due to its color and cost-effectiveness.

- Hemp: Hemp is a textile made from the fibers of the Cannabis sativa plant’s stalks, well-known for their remarkable strength and durability.

- Ramie: Ramie fiber boasts outstanding absorbency, becoming even stronger when wet, making it an ideal choice for heavy-duty textile applications.

- Sisal: Sisal fiber comes from the inner part of the large leaves of the Agave Sisalana plant, which is native to Southern Mexico. This plant is incredibly resilient, thriving in hot climates and arid regions, often in areas where other crops struggle. It can grow in various soil types, except for clay.

- Coir: The coir fiber is derived from a layer of fibrous pulp found beneath the outer leathery skin of Coconut.

- Pina: Pina fiber is a type of bast fiber obtained from pineapple plant leaves. These fibers are fine, soft, and lightweight, but they are often blended with silk or polyester to produce textiles.

Animal fibers:

Animal fibers are threadlike substances acquired from animals, such as fleece and silk. These strands are composed of protein molecules that include necessary elements such as carbon, hydrogen, oxygen, and nitrogen. Animal fibers are famous for their remarkable durability, but they tend to lose strength when they get damp because they have a restricted ability to transfer heat.

- Wool:

Wool fiber is a natural animal fiber acquired from the hair of sheep, mainly consisting of a protein called Keratin, which is its primary component. Wool also contains hydrogen, nitrogen, carbon, and notably, sulfur, setting it apart as the only natural fiber with sulfur in its composition. - Silk:

There are two types of silk fiber: mulberry, also known as cultivated silk, and wild silk. Cultivated silk is typically creamy white or yellowish-white in color, while white wild silk can range from brownish to golden yellow.

Mineral fibers: These are inorganic materials that have been processed into fibers, primarily used in the manufacturing of fire-resistant fabrics. Asbestos serves as an example of a mineral fiber. Mineral fibers are recognized for their fire-resistant qualities, resistance to acids, and industrial uses.

Types of Manmade fibers

Cellulosic:

Cellulosic fibers are part of a group of materials made from cellulose, which is sourced from materials like wood pulp and woody plants such as bamboo. The manufacturing process entails crushing or melting the raw material, mixing it with caustic soda, treating it with carbon disulfide, adding more caustic soda, and finally extruding it through a spinneret (similar to a fine sieve) into a bath of sulfuric acid to create the fibers.

- Rayon:

Rayon fiber, also referred to as viscose and sometimes marketed as sabra silk or cactus silk in specific areas, is a semi-synthetic textile fiber created from regenerated cellulosic material sourced from wood pulp. While it’s typically derived from wood obtained from eucalyptus, spruce, and pine trees, it can also be made using cotton or bamboo. - Acetate:

Acetate fiber, also known as cellulose acetate, is a semi-synthetic polymer used in the manufacture of textile fabrics for clothing. Its discovery can be attributed to the French chemist Paul Schützenberger in 1865. - Tri-acetate:

Triacetate is a partially synthetic textile created through the chemical fusion of cellulose. Triacetate fiber is renowned for its luxurious drape, making it a favored option for clothing that demands a graceful, fluid appearance.

Non-Cellulosic Polymers:

Non-cellulosic polymers refer to synthetic fibers that are not derived from cellulose, which is the natural polymer found in plant-based materials. Unlike cellulosic fibers, which come from sources like wood pulp and cotton, non-cellulosic polymers are created entirely through chemical processes and are often made from petroleum-based materials or other synthetic compounds. Examples of non-cellulosic polymer fibers include polyester, nylon, acrylic, and spandex.

- Nylon:

Nylon fiber consists of polymers called polyamides, which consist of carbon, oxygen, nitrogen, and hydrogen. - Aramid:

Aramid fibers are created from elongated synthetic polyamides. Para-aramid is renowned for its remarkable chemical composition, which primarily comprises poly para-phenyleneterephthalamide (PPTA). This polymer is formed by alternating benzene rings and amide groups, which gives it a rigid, rod-like structure. - Polyester:

Polyester is a synthetic or man-made fiber material. It gets its name from its technical name, polyethylene terephthalate (PET), which would be its legal name if it were a person. In a laboratory, polyester is produced by mixing ethylene glycol and terephthalic acid, essentially creating a type of plastic. - Acrylic:

Acrylic fiber is man-made from a synthetic polymer known as acrylonitrile. Acrylonitrile is derived from petroleum or coal-based chemicals and synthesized to produce acrylic resin pellets. These resin pellets are then shaped and extruded through a device resembling a showerhead called a spinneret. - Spandex:

Spandex is made from polyurethane. This polymer is first created through a process called polymerization, where different chemical compounds are carefully combined under controlled conditions to produce a long chain of repeating units. - Olefin:

Olefin fiber is made from polyolefins. It is recognized for its resilience, colorfastness, stain resistance, and durability, making it a versatile choice for various applications. - Vinyon:

Vinyon fibers are made through a process called wet spinning. In this method, the vinyl chloride polymer is dissolved in a solvent and then pushed through spinnerets into a coagulating bath. This bath solidifies the fibers, which are later washed, dried, and stretched to enhance their strength and stability. - Saran:

The fiber is relatively heavy compared to most clothing fibers. Saran fibers are used in upholstery for public transportation, deck chairs, garden furniture, and similar applications. However, their weight limits their suitability for broad use as a general textile fiber material. - Novoloid:

Novoloid, also referred to as phenolic fiber, is an organic thermoset fiber manufactured from phenolic novolac resin. - Polycarbonate:

Polycarbonates are common examples of synthetic fibers with lower crystallization tendencies. - Fluorocarbon:

Fluorocarbon textile fiber is also known as fluorocarbon-based fiber. That is made from polymers containing fluorine atoms.

You may also like:

- Structure and Properties of Cotton Fiber

- Identification of Textile Fibers

- Kapok Fiber: Properties, Structure and Production Process.

- What is Linen Fiber?

- Properties, Structure, and How It Made?

- What is Jute Fiber? Properties, Advantages and Disadvantages.

- What is Hemp Fiber? Properties, Advantages and Disadvantages.

- What is Ramie Fiber? Properties, Advantages and Disadvantages.

- What is Sisal Fiber? Properties, Structure, and How It Made?

- Wool Fiber: History, Properties, Production Process

- Silk Fiber: History, Properties, Production Process

- Count of Yarn: Explanation and Varieties

Share this Article!